|

|

#29

|

|||

|

|||

|

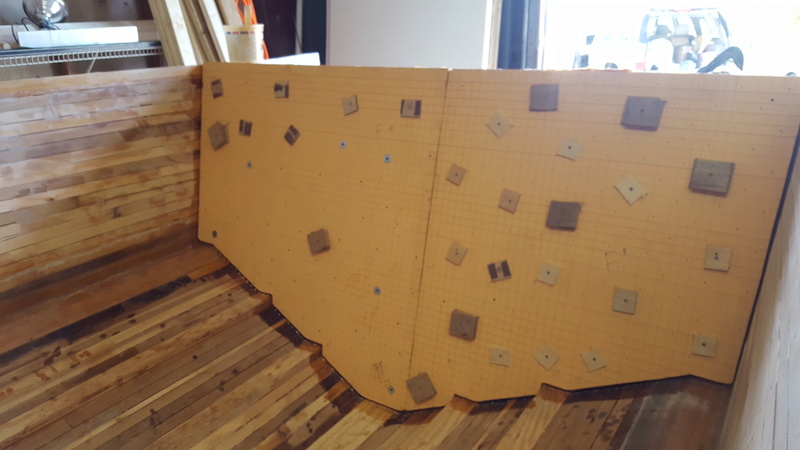

transom core is epoxied in place.

Dry fit, wet out surfaces with neat epoxy, apply epoxy glue (a mix of silica and wood flour), clamp/screw into place. both surfaces were very flat with a very nice fit, did not need a ton of glue. Used about 2 quarts of epoxy (before thickening) Total core thickness is 2.25" Design did not call for that much, but a had the 1.5" foam core, and it didnt add much weight. With the full size bracket, the loads are spread out over a large area, so the transom core really only needed to be 1"

__________________

http://www.boatbuildercentral.com/  my rebuild thread: http://www.classicseacraft.com/commu...ad.php?t=22090 |

| Thread Tools | Search this Thread |

| Display Modes | |

|

|