|

|

#1

|

|||

|

|||

|

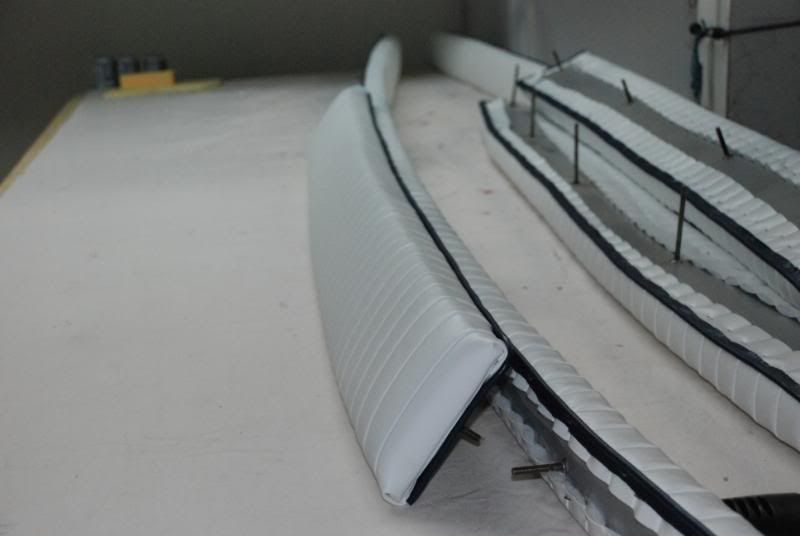

I recovered/rebuilt the bolsters in my boat. It'll have to warm up a bit before I install them. Next is the cushion in front.

|

|

#2

|

|||

|

|||

|

Very nice! You can do mine any time!

|

|

#3

|

|||

|

|||

|

Did you use stainless steel staples??

__________________

1977 SeaCraft 23' Sceptre W/ Alum Tower & Yamaha 225 www.LouveredProductsUnlimited.com |

|

#4

|

|||

|

|||

|

Quote:

|

|

#5

|

|||

|

|||

|

Someday I'm gonna learn how to do that. Looks great!!

strick

__________________

"I always wanted to piss in the Rhine" (General George Patton upon entering Germany) |

|

#6

|

|||

|

|||

|

Thanks guys!! My old Singer nor Vigorelli will go through more than two layers of this vinyl. It looks like I'll farm out the sewn cushion work.

|

|

#7

|

|||

|

|||

|

Great job ! I have wanted to do this for awhile - I don;t have any bolsters. I have a few questions:

- What is the backer material made of? - Where can I buy the SS 'bolts' that go through bolster and into boat - Where did you buy the the padded material ? - To do the bolsters, do you actually need to use a sewing machine ? Thx ! |

|

#8

|

|||

|

|||

|

- What is the backer material made of? Mine were plastic (starboard maybe) 3/8" thick. - Where can I buy the SS 'bolts' that go through bolster and into boat. Std. 1/4 20 screws the proper length. The "nuts" were ~ 1/16" thick SS threaded 1/4-20 ~ 5/8" square with the corners bent so to bite when tightened. - Where did you buy the the padded material ? - To do the bolsters, do you actually need to use a sewing machine ? If you want an inserted color you will need to sew it. I did not. www.garysupolstery.com and www.rochfordsupply.com I used ~ 6 yds. of pleated Capitano in chrystal white from Garys. I bought two (24 x 72) ea. of 1/2" and 1" closed cell xfirm #6130 and glued them together then cut to size. Fabric, foam, 25 yds. piping and monel staples ~ $400 and 10-12 hrs. time. |

|

#9

|

|||

|

|||

|

I've done a few in the past using cellular PVC. It's the stuff they are selling at Lowes for trim boards. It's very durable and will last forever. I used this because it is a bit softer so I could use stainless steel staples to hold the fabric to the backer. Using this material allows you to use stainless carriage bolts available at a well stocked marine supply. You can countersink the nut on the back side so the bolt won't spin and allows the pad to be installed flat. So far, the ones I have made are holding up. I made them for other people so I don't have pictures.

__________________

1975 SF18/ 2002 DF140 1972 15' MonArk/ 1972 Merc 50 http://i833.photobucket.com/albums/z...photos/SC3.jpg |

|

#10

|

|||

|

|||

|

I wish to make bolsters for my SeaCraft 23. I get it all except that I am agonizing over the foam. I have been told closed cell, open cell, and compressed foam. I want it soft on my 69 year old knees, but I don't want it so soft as to bottom out. I am hoping Closed cell foam will be soft enough. I would appreciate any input on this topic. Thanks.

Dennis Walsh |

|

|

|